In the era of rapid technological advancements, the concept of digital twins has gained significant traction across various industries. Originating from NASA’s Apollo space program, digital twins have evolved to become invaluable tools for enhancing engineering efforts, improving manufacturing processes, and delivering continuous services to customers. This article explores the paradigm shift from traditional digital twins to next-generation digital twins or also been addressed sometimes at BaseN as spimes, and their impact on product lifecycle management.

The Evolution from Digital Twins to Next-Generation Digital Twins

NASA’s adoption of digital twins marked a turning point in engineering practices. By creating digital replicas of physical objects, engineers gained easier access to valuable information and accumulated knowledge from multiple generations of hardware. The concept of digital twins subsequently extended beyond space exploration and found its way into heavy industry and manufacturing. Companies like Rolls-Royce and Dassault began leveraging digital twins to optimize their end products, such as jet engines and avionics systems.

However, the emergence of next-generation digital twins introduced a new perspective to the digital twin concept. While digital twins primarily focused on creating replicas, next-generation digital twins revolutionized the management of physical manifestations themselves. They encompass not only data collection and algorithm execution but also serve as virtual masters managing intellectual property, design, and code. They act as merchandise in their own right, offering a comprehensive solution that bridges the gap between the physical and digital realms.

The Advantages of Next-Generation Digital Twins

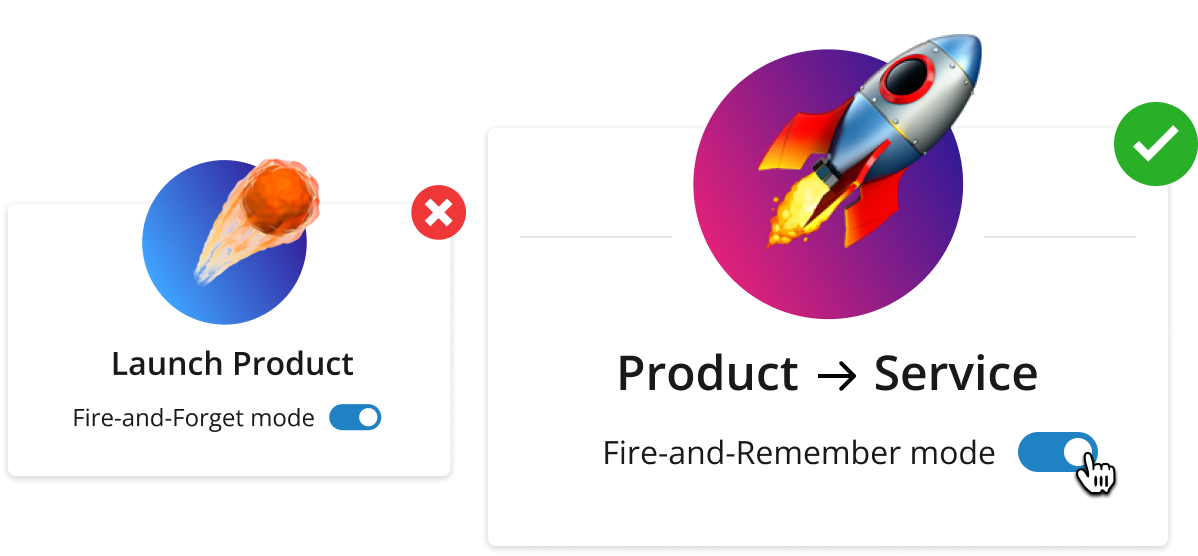

Next-generation digital twins not only enable data-driven decision-making but also emphasize transforming products into continuous services. This shift from a traditional fire-and-forget business model to ongoing customer engagement throughout the product lifecycle brings long-term sustainability and better customer understanding. With next-generation digital twins, manufacturers can remain connected with their customers in real-time, adapting to their evolving needs and preferences. This seamless interaction fosters stronger customer relationships and promotes continuous improvement.

Furthermore, these virtual masters drive digitalization and automation, paving the way for enhanced efficiency and productivity. Although concerns about job displacement arise, the global digital twins’ market has the potential to create meaningful and creative employment opportunities. By capturing and preserving knowledge and experience, next-generation digital twins facilitate the effective evolution of ideas and algorithms. The seamless transfer of expertise from retiring employees ensures the continuity of innovation and the preservation of valuable insights.

📌 Read more about digital twins vs. next-generation digital twins in our summarized eBook.

Embracing Next-Generation Digital Twins for Future Success

In an increasingly competitive landscape, staying ahead of customer needs is paramount. Next-gen digital twins empower businesses to gain real-time insights into customer behavior and preferences, enabling them to make informed decisions and respond swiftly to market trends. By leveraging this technology, companies can build a sustainable, efficient, and secure infrastructure to move spimes across evolving hardware. This approach not only ensures ultra-reliable services but also enhances customer satisfaction and loyalty.

The transition from digital twins to next-generation digital twins marks a significant advancement in product lifecycle management. By embracing next-generation digital twins, businesses can unlock the potential for enhanced customer engagement, continuous service delivery, and real-time decision-making. Next-gen digital twins offer a comprehensive solution for bridging the gap between the physical and digital worlds, revolutionizing how companies understand and interact with their products.