As the world embraces the era of digital transformation, new and groundbreaking technologies are emerging to redefine the landscape of product design and maintenance. Among these innovations, next-generation digital twins stand out as a powerful solution capable of transforming the way we optimize, monitor, and predict the behavior of products and systems in the real world.

But what exactly are Next-Generation Digital Twins?

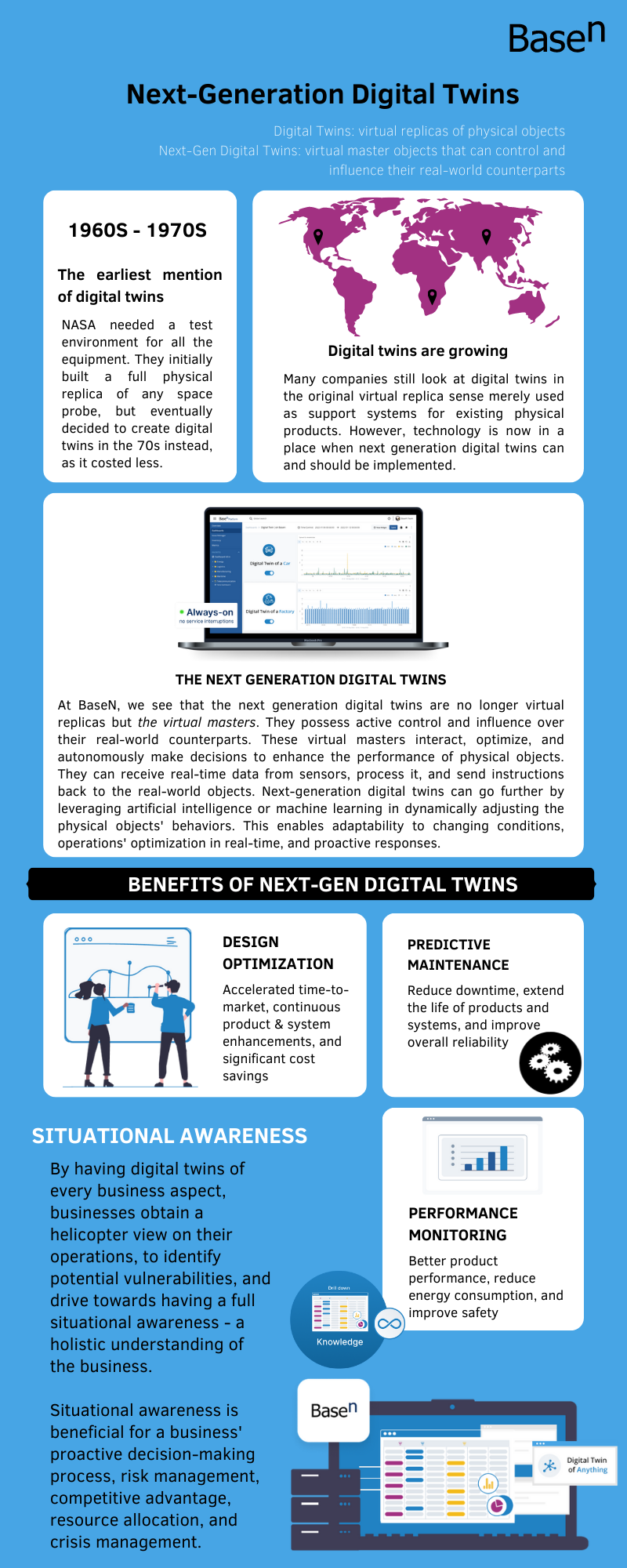

Next-generation digital twins are advanced virtual masters of physical objects, such as products or systems, that leverage cutting-edge technologies like sensors and other data sources to capture comprehensive information about their design, operation, and environment. This data is constantly fed into the next-gen digital twin in real-time. By that, the twin analyses their behavior and performance across a range of conditions. Embracing next-gen digital twins unlocks a vast ecosystem of opportunities for product manufacturers and service providers.

Why Embrace Next-Generation Digital Twins?

Next-generation digital twins offer a myriad of benefits across diverse applications, spanning from design optimization to predictive maintenance and performance enhancements. Let’s explore how embracing these advanced digital twins can revolutionize products and systems:

1. Design Optimization: By leveraging the capabilities of next-generation digital twins, product or system performance can be automatically simulated and optimized under various conditions, eliminating the need for extensive manual intervention. This autonomous process allows for faster time-to-market, exceptional product performance, and significant cost reductions. The self-driven nature of next-gen digital twins revolutionizes the development landscape, empowering products and systems to reach their full potential effortlessly.

2. Predictive Maintenance: The real-time monitoring capabilities of next-gen digital twins enable them to autonomously detect and address potential issues before they manifest. This self-sufficient capability eliminates the reliance on human intervention, effectively minimizing downtime, extending the lifespan of products and systems, and elevating overall reliability. The autonomous nature of next-generation digital twins ensures a proactive and seamless maintenance approach, maximizing operational efficiency and reducing potential disruptions.

3. Performance Monitoring & Control: Next-generation digital twins autonomously identify areas for performance enhancement, eliminating the need for human intervention. This self-driven process results in improved product performance, reduced energy consumption, and heightened safety measures. By leveraging their advanced capabilities, next-gen digital twins continuously analyze data and make independent adjustments to optimize performance, ensuring optimal efficiency and safety standards are met without requiring human intervention.

Next-generation digital twins introduce an exciting and transformative technology that revolutionizes the way we design and maintain products and systems. Through their autonomous capabilities, next-gen digital twins create virtual replicas of physical objects, enabling them to independently optimize designs, accurately predict behavior, and elevate performance in real-world conditions. Next-gen digital twins proactively enhance designs, accurately forecast outcomes, and elevate performance to new heights.

As the adoption of next-gen digital twin technology grows, we can anticipate even more remarkable and innovative applications in the coming years. The future holds immense potential for harnessing these advanced digital twins to propel industries forward, enabling smarter and more efficient product design and maintenance.