In the rapidly evolving landscape of the automotive industry, car manufacturers are at a crossroads. Traditionally, their focus has been on producing vehicles efficiently, with the customer relationship often taking a back seat. However, the digital age has ushered in a new era where the customer is not just king but kin. The success of car manufacturers now hinges on their ability to serve and enhance the customer’s core business continually. Welcome to the real service business.

The Missed Opportunities in Car Manufacturing

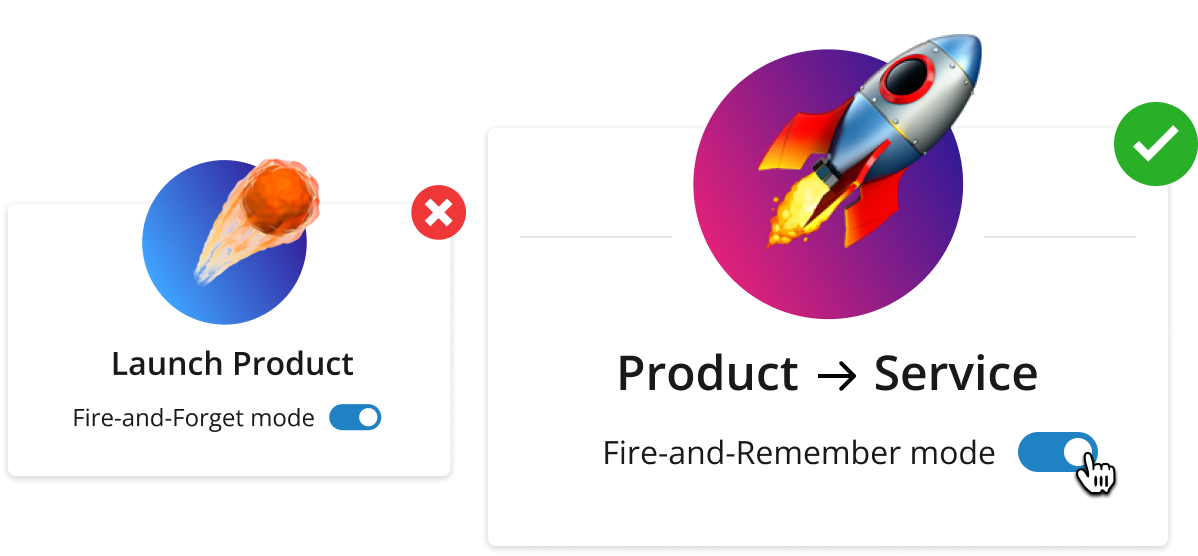

Car manufacturers have a wealth of untapped data at their disposal. Each car already has a form of Digital Twin, containing data from the production line. However, the potential of this data remains largely untapped. Manufacturers have been stuck in a ‘fire-and-forget’ mode, where car usage data becomes virtually unused after the sale.

Imagine a scenario where, years after a car purchase, the manufacturer can provide relevant, personalized services to the customer. This is not just about sending a standard ad; it’s about preempting and projecting customers’ needs and wishes, including broader values like corporate social responsibility and environmental sustainability.

From Fault Detection to Customer-Centricity

One of the critical aspects of this transformation is the ability to detect faults and make accurate diagnoses in real time. This requires setting proper thresholds and relying on a reliable digital platform that acts as the car’s hosting base. With these mechanisms in place, manufacturers can create relevant alerts for users, ensuring that major issues do not go unnoticed.

This fault detection, coupled with predictive insights, root cause analysis, and situational awareness, is not limited to the automotive sector alone. It extends to eHealth initiatives, where real-time monitoring and timely interventions can make a significant difference in patient care.

Next-Generation Digital Twins: A Logical Step

To fully leverage this potential, manufacturers must move beyond their existing Digital Twins. A next-generation digital twin, an alive virtual master that accompanies the car from production to recycling, is the logical next step. This comprehensive digital twin is the foundation for the customer-centric transformation.

The Shift to Customer-Centricity

In this new paradigm, the car manufacturer’s most precious asset is the relationship with the end customer. A car is a significant investment, and with a data privacy-conscious approach, manufacturers can build an arsenal of transportation-related services tailored to each customer. The challenge lies not in collecting data, which already exists in abundance, but in changing the mindset of management.

The focus is no longer on ‘concentrating on the core business’ or ‘making production as efficient as possible.’ Instead, it’s about preempting and projecting customers’ needs and wishes, including broader values like corporate social responsibility and environmental sustainability. This requires daily attention to every customer, treating them as kin and understanding their needs at every moment.

Embracing a New Service Business Model

In the era of digital twins, next-generation digital twins, and the Internet of Things, technology problems take a back seat to those of legacy common practices and experience. The only way forward is to unlearn the lessons of the past century and embrace the idea that every product is a service with a carefully managed lifecycle.

Whether you’re producing roof tiles or blast furnaces, the inherent customer connection must be built into every product and service. This is the path to customer-centricity, and it’s the future of car manufacturing and many other industries in the digital age.